How are spunbond nonwoven fabrics used in diapers produced?

Jan 02, 2025

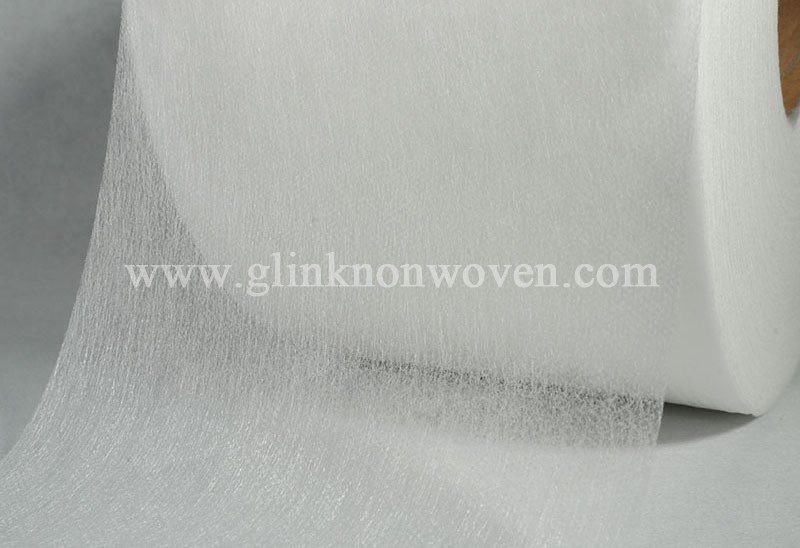

Spunbond nonwoven fabrics are widely used in the production of diapers, especially in the structure of their outer layer and moisture absorption layer. The process of producing spunbond nonwoven textiles mainly includes the following steps:

1. Polymer preparation (raw material selection)

The raw materials of spunbond nonwoven fabrics are usually polypropylene (PP) or polyester (PET), which are widely used in nonwoven production due to their excellent mechanical properties, chemical stability and cost-effectiveness. Polypropylene is usually used in the production of diapers.

2. Melt Spinning

In the melt spinning process, the polymer raw material is first heated to its melting point and becomes molten. The molten polymer is then extruded through a spinning nozzle through small holes to form long and thin fibers.

These fibers are not woven or knitted by traditional textile methods, but are directly formed from the ejected molten polymer filaments.

This spinning method can quickly produce a large number of fibers and can accurately control the diameter of the fibers.

3. Cooling and solidification

The polymer fibers extruded from the spinning nozzle pass through a cooling zone (usually by air cooling), during which the molten polymer quickly solidifies into solid fibers.

4. Formation of the fiber web (web formation)

When these cooled fibers are ejected onto a mesh frame or collecting belt, the fibers are randomly arranged to form a fiber web (the prototype of nonwoven fabric). This web can be treated and compacted in different ways to form connections between the fibers.

Electrostatic or mechanical action: Sometimes, the fiber web is strengthened by electrostatic adsorption or mechanical methods (such as needle punching, heat pressing, etc.) to make the web structure more compact and enhance the strength of the nonwoven fabric.

Thermal bonding: Some spunbond nonwovens use a thermal bonding process to fix the fibers, that is, heating to melt and bond the contact points between the fibers.

5. Post-processing and finishing

After the initial formation of nonwoven fabrics, they usually go through further post-processing steps, such as:

Drying: Remove excess water and solvents.

Surface finishing: For example, by surface coating or electrostatic treatment, the performance of non-woven fabrics is improved, such as enhanced breathability, waterproofness, etc.

Cutting and molding: According to the required size, the non-woven fabric is cut into suitable sizes for different products.

6. Quality control and testing

Finally, the non-woven fabric must undergo a series of quality tests before leaving the factory, including tests on thickness, strength, uniformity, breathability and other properties to ensure that it meets the use requirements of products such as diapers.

The key to the production of disposable nonwoven fabric is to melt the polymer and spin it into fibers through melt spinning technology, and then process it into the final non-woven fabric product through mesh molding and post-processing. Its advantages include high production efficiency, low cost, and recyclable materials. It is widely used in diapers, medical, hygiene and other disposable products.

Read More