ADL, the full name is Acquisition Distribution Layer, which is an important term in the field of maternal and child health products, especially playing a key role in products such as sanitary napkins and diapers. Its main function is diversion and diffusion control, aimed at improving product performance and user comfort.

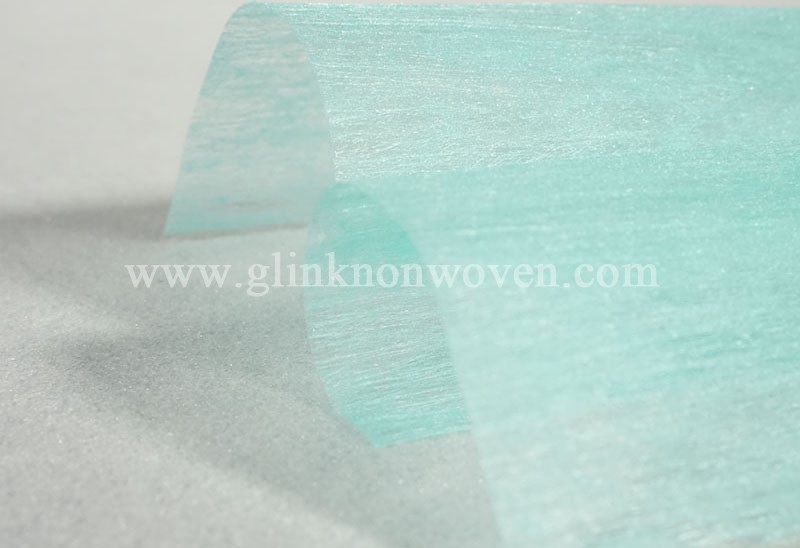

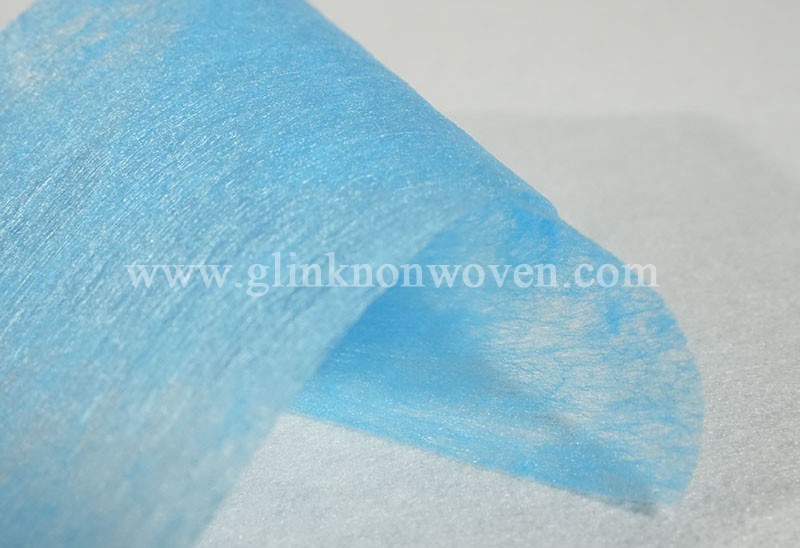

As a special non-woven fabric, ADL nonwoven raw material is located between the surface material of sanitary products and the absorbent core. Its existence enables the liquid to quickly conduct from the surface to the inner layer, forming an efficient absorption process. Through this method, ADL helps to evenly distribute liquids and quickly remove them from the user's skin, thereby maintaining a dry and dry state of the skin.

Specifically, the three major functions of ADL are as follows:

Promote rapid absorption of liquids: The design of sanitary napkin ADL nonwoven helps to transfer liquids to the core from the first moment they come into contact with the skin, reducing retention and improving absorption speed.

Temporary storage of liquids: During the absorption process, ADL can temporarily store a certain amount of liquid to avoid excessive expansion or leakage, and maintain the integrity of sanitary products.

Distribution and diffusion conduction: The diffusion effect of ADL quick guide layer nonwoven helps to evenly distribute the liquid, making the overall performance of the product more stable and ensuring a comfortable user experience during use.

Through the design of ADL, the use of polymer absorbent resin (SAP) can be effectively reduced while maintaining product quality, which not only reduces costs but also has a positive impact on environmental protection.

If you want to get more information about our products, you can click www.glinknonwoven.com.