What do you need to know if you want to enter the diaper industry and produce baby diapers?

Apr 01, 2025

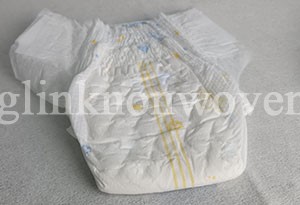

If you want to produce disposable baby diapers, here are some guidelines to help you plan the entire process from raw material preparation to finished product inspection:

1. Market research and product positioning

Understand market demand: Study the consumer demand of the target market, the product characteristics of competitors and market trends, and determine the differentiated positioning of the product.

Determine product specifications: According to market demand, determine the key indicators of diapers such as size, absorption capacity, breathability, and softness.

2. Diaper raw material preparation

Spunbond non-woven fabric: As the main product of your factory, spunbond non-woven fabric is an important raw material for the surface layer, diversion layer, and leak-proof edge of diapers. Ensure that the quality of raw materials meets national standards and customer needs.

Absorption layer material: such as polymer absorbent resin (SAP), which is the core absorbent material of diapers, needs to choose products with strong water absorption and good water retention capacity.

Backsheet film material: such as PE breathable bottom mold or hot air breathable bottom mold, responsible for preventing urine leakage and maintaining good breathability.

Elastic materials: such as elastic waistbands, used to improve the fit and comfort of diapers.

3. Production process

Raw material cutting and pretreatment: Cut spunbond non-woven fabrics, absorbent layer materials, bottom films and other raw materials according to the designed size, and perform necessary pretreatment, such as hydrophilic treatment, softening treatment, etc.

Assembly and molding: Assemble the cut raw materials in a certain order to form the basic structure of diapers. Through the molding machine, the diapers are pressed into the required shape and size.

Adding functional layers: Add functional layers such as humidity indicators and leak-proof edges to diapers as needed to improve the practicality and comfort of the product.

Heat sealing and bonding: Use hot melt adhesive or other bonding methods to firmly bond the layers of materials together to ensure that the diapers will not delaminate or shift during use.

Quality inspection: Perform water absorption performance tests, strength tests, appearance inspections, etc. on the finished diapers to ensure that the product quality meets national standards and customer needs.

4. Production equipment and automation

Introduction of advanced production equipment: Consider the introduction of highly automated production lines to improve production efficiency, reduce labor costs, and ensure the consistency of product quality.

Intelligent monitoring: Use advanced technologies such as machine vision systems and sensor networks to monitor key parameters in the production process in real time, and promptly discover and solve problems.

5. Quality control and environmental protection measures

Establish a quality management system: Develop a complete quality management system and process to ensure that every link from raw material procurement to finished product delivery meets quality requirements.

Strengthen environmental protection management: During the production process, take necessary environmental protection measures, such as reducing wastewater discharge and reducing noise pollution, to ensure that production activities comply with environmental protection regulations.

6. Sales and distribution

Establish sales channels: According to market demand and competition, select appropriate sales channels, such as direct sales, distribution, e-commerce, etc.

Develop marketing strategies: Combine product characteristics and market demand to develop targeted marketing strategies to increase product awareness and market share.

7. Continuous improvement and innovation

Pay attention to market trends: Pay close attention to changes in market trends and consumer demand, and adjust product strategies and production plans in a timely manner.

Technological innovation: Continuously introduce new technologies and new materials to improve product performance and comfort and meet the diverse needs of consumers.

In summary, the production of diapers requires comprehensive consideration of market demand, raw material preparation, production process, production equipment and automation, quality control and environmental protection measures, as well as sales and distribution. I hope the above suggestions can help you.

If you need know more information, please click www.glinknonwoven.com

Read More