Types and applications of hot melt adhesives for sanitary materials

Dec 31, 2024

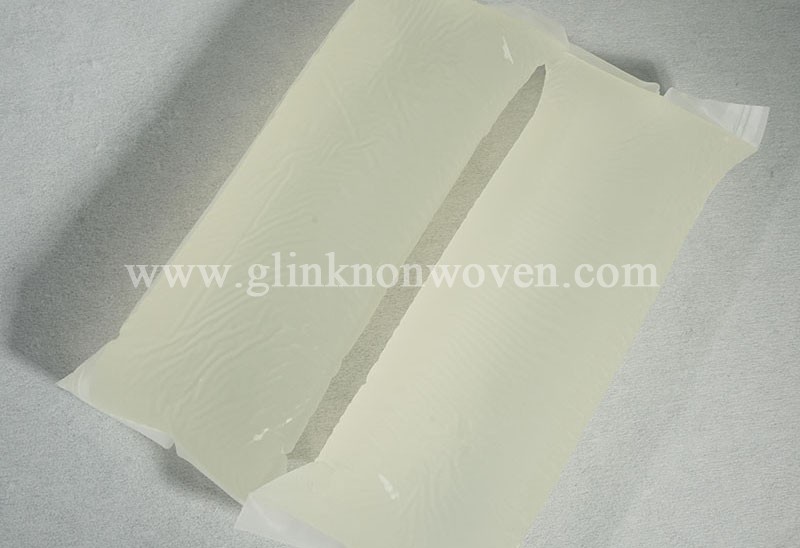

The adhesives used in disposable sanitary products are mainly hot melt adhesives based on thermoplastic polymers. This material is applied in a molten state, can wet the adherend, and can achieve rapid bonding by applying light pressure after cooling and hardening. Its main types cover a variety of special adhesives, as follows:

1.Position adhesives are mainly used for the back layer of sanitary napkins. It can firmly stick the sanitary napkin to the underwear and effectively prevent movement. The adhesive has moderate cotton cloth peeling force and excellent anti-transfer performance. It has strong adaptability to seasons and regions and can maintain initial adhesion even in low temperature environments. In addition, it has light color, low odor, is not sensitive to ultraviolet light, is safe and non-toxic to use, and is not easy to cause allergies.

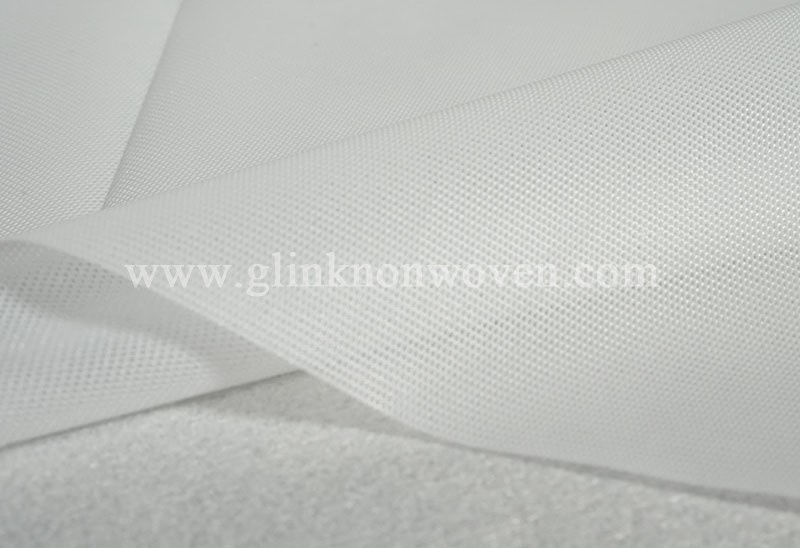

2.Construction adhesives are specially used for bonding non-woven fabrics, perforated films and PE back films, as well as absorbent paper and non-woven fabrics, PE or fluff pulp and other materials. At the same time, it can also effectively bond elastic waistbands and PE back films. Structural adhesives have good thermal stability and suitable open time, and have excellent bonding effect on PE film and non-woven fabrics, no reverse osmosis, no scalding of PE film, and excellent performance on the machine.

3.Elastic adhesives are mainly used to fix elastic materials, so that they can be better bonded to non-woven fabrics and base films, thereby enhancing the close-fitting comfort and leak-proof performance of the product. Elastic adhesives have high creep resistance, good thermal stability and suitable open time, and have good bonding effect on elastic materials and PE backing materials or non-woven fabrics, no reverse osmosis, and are soft and elastic.

4.Wetness indicator adhesives are a kind of hot melt pressure-sensitive adhesive containing PH color developer, which will change color when wetted with urine, playing a prompting role. During use, the glue temperature and parking time of urine indicator adhesive in the glue machine must be strictly controlled to prevent excessive aging and loss of urine indicator function.

These hot melt glues have been widely used in disposable sanitary products such as sanitary napkins, diapers and other products, ensuring that the products have good bonding performance and user experience during use.

Read More