What raw materials can be used for sanitary napkin topsheet materials?

Jan 24, 2025

Sanitary napkin topsheet materials can use a variety of raw materials, the following are some common ones:

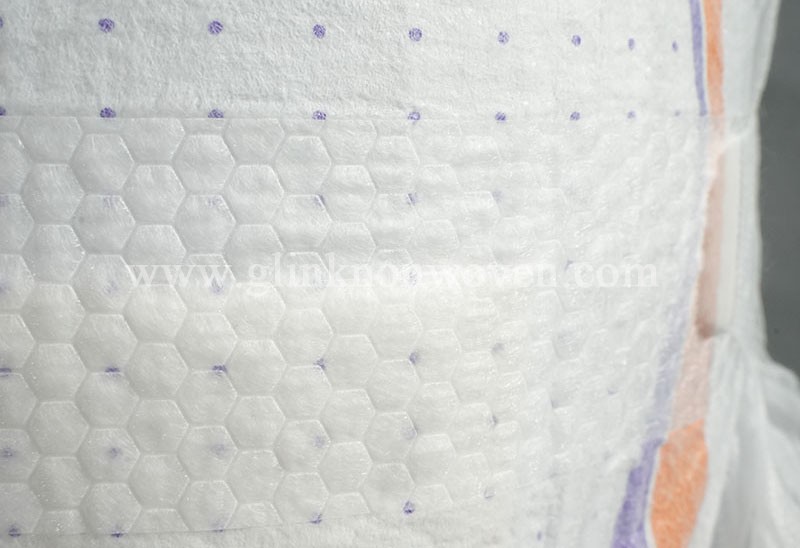

Dry mesh material: The surface of this sanitary pad is made of polyethylene (PE) film with small holes, also known as perforated film. It has the advantages of fast absorption and long-lasting dry surface. However, because it is a chemical fiber component, it may cause allergic reactions such as itching, redness and swelling for women with sensitive skin.

Cotton surface material: The cotton surface is not pure cotton, but is made of non-woven fabrics such as polypropylene (PP). This material is soft and can give people a touch similar to pure cotton, but it has poor breathability and may make private parts feel stuffy during use. In addition, bleaching may be required during the production process, so most cotton surface sanitary napkins contain additives, but the allergenicity is relatively low.

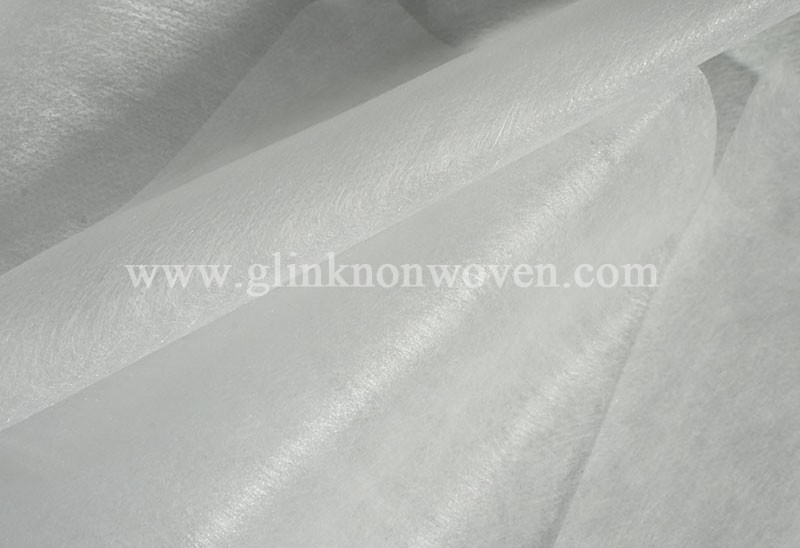

Pure cotton surface material: The pure cotton surface is made of natural cotton fibers interwoven into a uniform, thin and soft non-woven fabric. This material is soft and comfortable, with minimal irritation to the skin, and is suitable for most women. Compared with chemical fiber materials, pure cotton sanitary napkins are more skin-friendly and can reduce allergies. However, pure cotton products tend to turn yellow over time, and are prone to breeding bacteria and mites at a certain temperature of the human body.

In addition to the above materials, some sanitary napkins use high-quality non-woven materials such as hot air non-woven fabrics as the surface layer. These materials are soft, breathable, and not easy to irritate the skin.

In general, the choice of sanitary napkin making raw materials depends mainly on personal skin conditions, needs, and budget. For women with sensitive skin, it is recommended to choose sanitary napkins made of natural materials such as pure cotton, silk or bamboo fiber; and for women who pursue a dry experience, dry mesh sanitary napkins may be a good choice.

Read More